Home - Techniek - Electronica - Radiotechniek - Radio amateur bladen - QST - Semiconductor heat sinks

Homemade heat sinks can be fashioned from brass, copper or aluminum stock by employing ordinary workshop tools. The physical dimensions of the heat sink will depend upon the type of transistor used, and the amount of heat that must be conducted away from the body of the semiconductor.

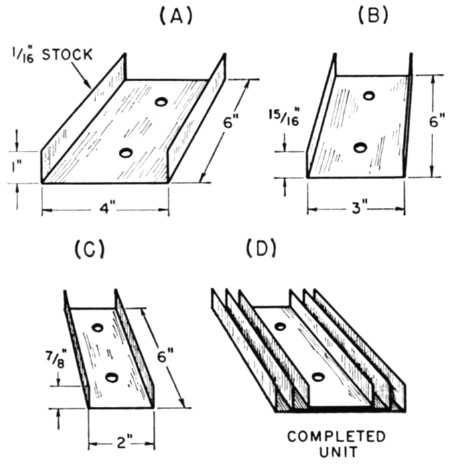

Fig. 1 shows the order of progression for forming a large heat sink from channels of near-equal height and depth. The width is lessened in parts B and C so that each channel will fit into the preceding one as shown in the completed model at D. The three pieces are bolted together with 8-32 screws and nuts. Dimensions given are for illustrative purposes only.

Fig. 1. Details for forming channel type heat sinks.

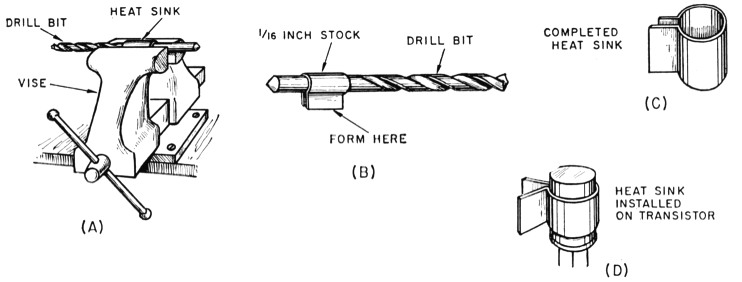

Heat sinks for smaller transistors can be fabricated as shown in Fig. 2. Select a drill bit that is one size smaller than the diameter of the transistor case and form the heat sink from 1/16 inch thick brass, copper or aluminum stock as shown in steps A, B and C. "Warp" the stock around the drill bit by compressing it in a vise (A). The completed heat sink is press-fitted over the body of the semiconductor as illustrated at D. The larger the area of the heat sink, the greater will be the amount of heat conducted away from the transistor body. In some applications, the heat sinks shown in Fig. 4 may be two or three inches in height (power transistor stages).

Fig. 2. Steps used by W1CER in constructing heat sinks for small transistors.

W1CER.