Three-band quad for field day

Transportable array for 10, 15 and 20 meter.

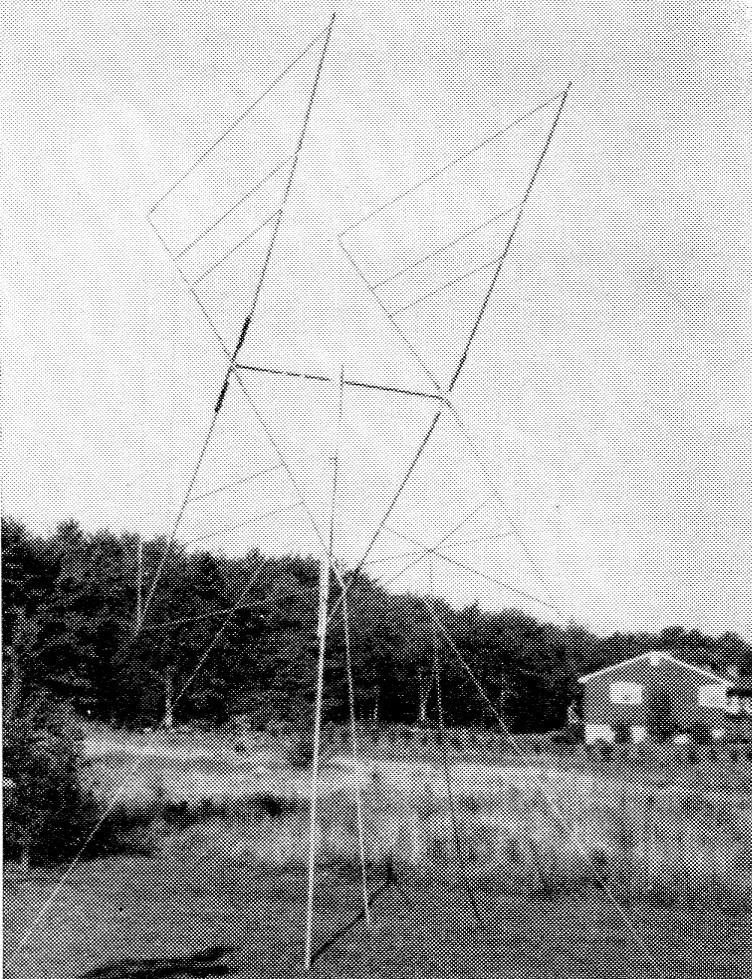

Although the quad antenna described in this article was designed specifically with portability in mind, we have a strong suspicion that more than a few will be tempted to try it for homestation use. It should be well suited for both purposes.

Field day always brings out innovations in antenna arrays. One answer to this need is a cubical quad - a three-band quad that can be assembled and dismantled with ease and which is collapsible to a size that is readily transported in a car. This seemed like an impossibility at first, but it was decided that an attempt would be made anyway.

For quick assembling and dismantling, it was obvious that it should not be necessary to restring the six wire loops each time. This problem was solved by using stranded wire for the elements and fastening them permanently to the spreaders. The spreaders, with the element wires still attached, may be formed into two neat bundles when the spreaders are detached from the mounting spiders. The elements, being semi-flexible, are not damaged by this process. The mast is cut into two sections, and the remaining components are small enough to present no problem.

The spider

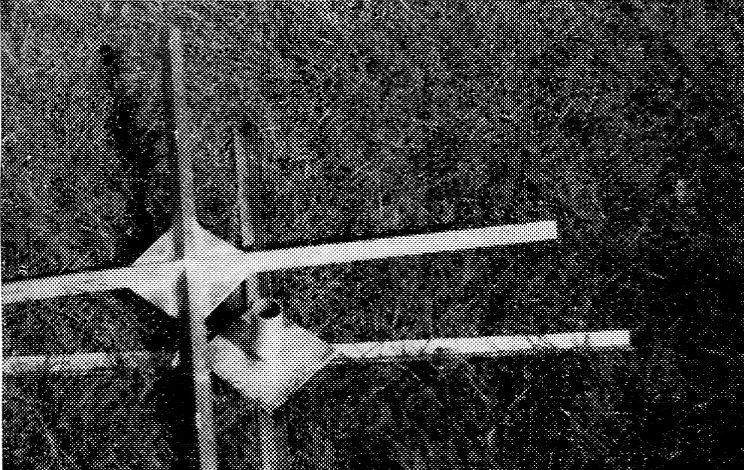

The mechanical heart of any quad antenna is the spider - the mounting for the spreaders. These were made as shown in one of the photographs. One 4-foot length and two 2-foot lengths of 1¾ × 3/16 inch aluminum angle are welded, at right angles and face downward, to one face of a 6¼ inch square, of ¼ inch aluminum sheet. At the center of the square on the opposite side, a 4½ inch length of aluminum tubing is welded. This tubing has an outside diameter of 2 inch and a wall thickness of 0.25 inch. The outside diameter is shaved down so that it will make a snug fit inside the end of the boom. This construction makes a very rigid support for the spreaders and will take the strain of hauling the quad up and down. All material should be grade 6061-T6.

After fabrication of a few simple components, this three-band quad can be put up by two or three men in a matter of minutes.

Spreaders

The spreaders are 12-foot bamboo poles. They are fastened in the spider legs, by means of stainless-steel strap-type clamps, in such a position that the butt ends of diagonally-opposite spreaders are separated 18 inches. To facilitate rapid assembly, a paint mark at the point where each butt should rest will be helpful.

Elements

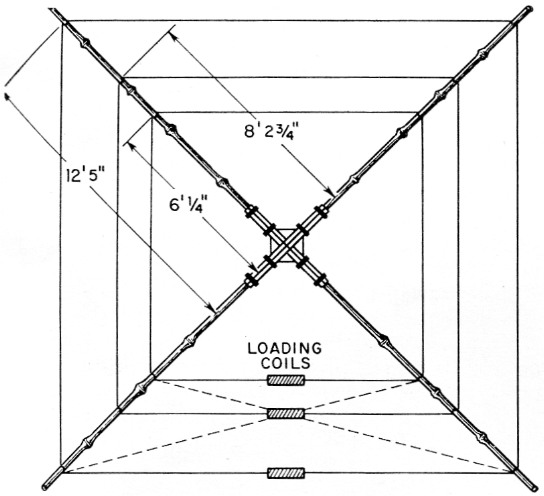

The sketch of Fig. 1 shows the dimensions of the elements which are made of stranded aluminum clothesline (about 1/8 inch in diameter). The driven elements and the parasitic elements have the same physical dimensions. The reflectors, however, are tuned to a lower frequency by inserting a loading coil in each. The dimensions of the elements and the loading coils are based on frequencies centered on what have proven in the past to be the most productive segments of the three bands in Field Day operation. These segments are the c.w. section of the 20 meter band, the entire 15-meter band, and the phone portion of the 10-meter band. The three driven elements are connected together at the feed points, as indicated by the dashed lines in Fig. 1, and are fed by a single coaxial line.(1)

Fig. 1. Sketch showing the dimensions of the parasitic elements. Dimensions for the driven elements are the same, but there are no loading coils and the bottom ends are brought to a common feed point as indicated by the dashed lines.

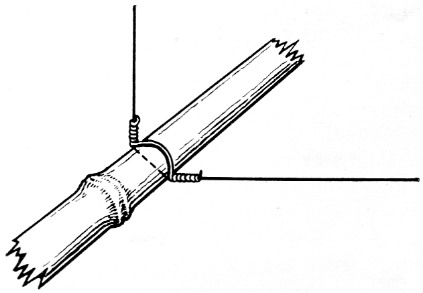

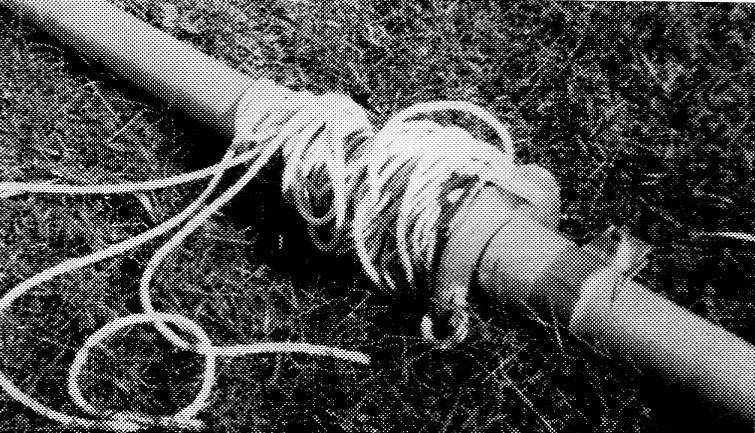

After the spreaders have been mounted on the spiders, the distances shown in Fig. 1 are marked the off and 1/8 inch holes are drilled through the bamboo. The clothesline is fed through the holes, and then the spreaders are squared up. To preserve this alignment, stainless steel tie wires are used which prevent slippage of the clothesline in the holes. See Fig. 2. The ties should be given a coat of epoxy, and the bamboo poles may be protected against weather by applying boat resin.

Fig. 2. Sketch showing the manner in which the element wires are tied to prevent slipping at the spreaders.

A 1 × 3 inch piece of h-inch Plexiglas is drilled to form the insulator at the feed point of the 15 meter driven element. The open ends (feed points) of the 10 and 20 meter driven elements are brought to this same insulator where all three elements, and the RG-58/U transmission line, are connected in parallel. In each of the parasitic elements, the free ends of the clothesline are brought to the respective loading coils.

Boom and mast

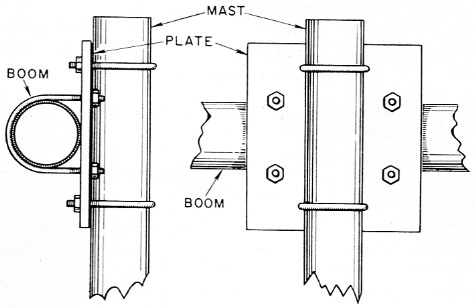

A 30 foot length of 2 inch aluminum irrigation pipe (0.05 inch wall) is cut up into three sections - two sections of 10½ foot each for the portable mast, and one of 8½ foot for the boom. The ends of the boom are slit for a short distance, and clamps are used to secure the connection to spider. Care should be taken to keep the inside surfaces of the boom ends, and the outside surfaces of the short sections of tubing welded to the spiders, free from burrs or grit of any kind, since these may cause the joint to freeze up, making it difficult to detach the spiders from the boom. It is a good idea to coat each of the surfaces with heavy grease, such as DC-4.The two sections of the mast are joined together by a dowel insert which makes a snug fit inside the tubing. Wood screws are used to fasten the tubing to the insert, and the joint is reinforced with adjustable clamps on either side.

A pair of sturdy quad "spiders" made from aluminum stock. The supporting arms of angle and the tubular boom coupling are welded to the square plate.

The butt ends of the spreaders are fastened in the grooves of the spider arms by means of stainless-steel clamps.

The driven elements are fed in parallel by a single transmission line of RG-58/U coax. Stainless-steel washers on stainless steel screws separate the copper of the line and the aluminum of the elements.

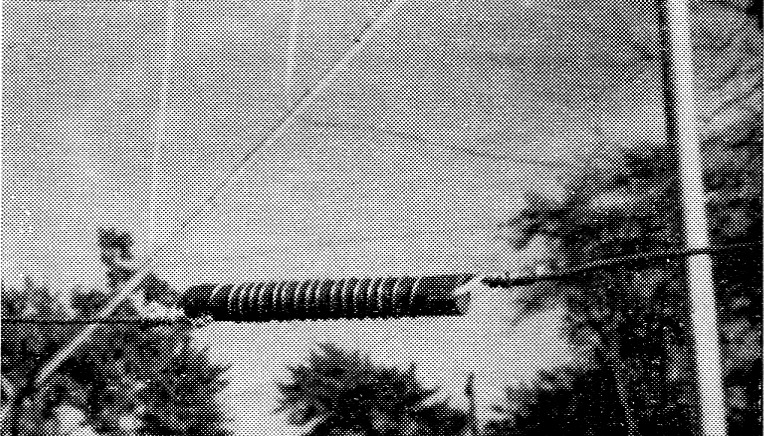

The loading coils for the parasitic elements are wound on 6 inch lengths of 34 inch phenolic rod, all to a winding length of 4½ inch. The conductor is one strand of the aluminum clothesline used for the elements. The 20-meter coil has 16½ turns, the 15 meter coil 16 turns and the 10 meter coil 14 turns for the design frequencies used by the author. After winding, the coils should be coated with boat resin or varnish.

The quad "package." The boom, and mast sections, with guys wrapped around the upper section, are in the foreground. To the rear are the spiders, and spreaders wrapped in a protective covering.

A hardwood dowel joins the two sections of the mast.

At a point about 3 feet down from the top of the mast, a clamp made of 1/8 inch aluminum is fastened to the mast. Immediately above the clamp is a spacer about 2 inches long made of aluminum tubing that will slide easily over the mast. The clamp serves as a stop for the guy ring, and the spacer keeps the guys clear of the clamp.

Three guys of nylon rope are used. A total of about 100 feet will be adequate. Nylon rope has great tensile strength, but it will not stand up well under abrasion and therefore must be protected from chafing against sharp edges. The holes in the guy ring are fitted with metal "thimbles." The guy rope is looped around the thimble and the free end is tied back on the standing part of the rope with twine.

There are several ways in which the boom may be attached to the mast. One method using a metal plate and U bolts is shown in Fig. 3.

Fig. 3. A metal plate and four U bolts may be used to attach the boom to the mast.

Putting the antenna up

In erecting the quad, a few pointers may be helpful. With one set of spreaders and elements mounted on a spider, lay the assembly flat on the ground with the boom stud of the spider facing upward. Hold the boom vertically and fasten it to the spider. Assemble the other set of elements and likewise place it flat on the ground. Then swing the boom with the first set of elements attached up into an inverted position and fasten the second end of the boom to the second spider. Assemble the mast and attach it to the center of the boom. Then raise the mast to a vertical position and anchor the guys. The total weight, including the mast, is only 47 pounds, so two men can easily hold the mast vertical while the guys are being secured.

Guying ropes, guy ring, spacer and clamp.

Adjustment

The reflector loading coils were adjusted for maximum front-to-back ratio using a field-strength meter. In doing this, the quad was mounted close enough to the ground so that the 20-meter loading coil could be reached. Then a stepladder was used to reach the other two loading coils. When the antenna was raised to its full height, the adjustments of the 10 and 15 meter elements were found to remain satisfactory. However, the frequency of maximum front to back ratio on 20 increased by about 50 kilocycles, so it is probably advisable to make the initial adjustment for a frequency somewhat lower than the target frequency on this band.

Packing for transport

To avoid any possible confusion, it is a good idea to code the four spreader poles in each element with numbers. In dismantling the antenna, use the reverse of the procedure described for assembling. Lower the assembly so that one element lies flat on the ground; detach the mast. Then disconnect the boom from the element lying on the ground, invert the boom, placing the other element flat on the ground, and remove the boom. On each element, remove the spider, without disturbing the positions of the spreaders. Fold one spreader arm back over on top of the opposite one. Swing the two remaining arms parallel to the first pair, keeping the element wires reasonably taut. Then roll the two side spreaders toward the center pair, winding up the wire on the spreaders as you go. Wrap the bundle in a protective wrapping (I used tar paper because it was handy) and secure with twine. With a maximum length of 12 feet, the quad in knockdown form can be easily transported in a station wagon or on a ski rack.

Materials

The total cost of materials for the quad is about $55.00. A 30 foot length of 2 inch irrigation pipe can be obtained from Sears for approximately $8.50. Material for the spider is generally available from dealers in metal stock - look in your phone book. "Heliarc" and other welding facilities are becoming more numerous every day and are now located in most cities. Again - consult your telephone directory. The author obtained the bamboo spreaders from the Mohawk Venetian Blind Co., 36 Cameroon Ave., Cambridge, Mass. There are other sources in both east- and west-coast areas. Be sure to ask for poles that are free from cracks. Aluminum clothesline is available in hardware stores. You will need about 350 feet. The brand I happened to find is called Aluminum Dog Run and is manufactured by Nichols Aluminum and Wire Co., Davenport, Iowa. It is guaranteed not to oxidize - an advantage in this application as well as in the originally intended one.

Both electrically and mechanically, this quad has performed in excellent fashion. The first night on its Field Day christening at K1DRX/1 set up at Mt. Ascutney, Vermont, it withstood 40- to 50-m.p.h. gales, remnants of a tornado, with no damage.

Notes

Ernest H. Adolph, K1DRX.