Nonconductive Guys

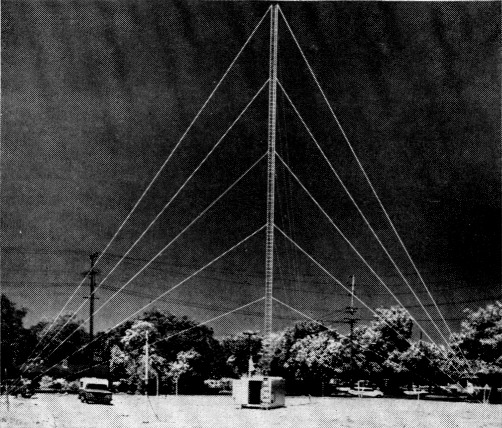

A 100-foot transportable tower supported by Mylar guy line. The tower is used for experimental purposes at Stanford University.

Minimizing antenna-pattern distortion

Commercial and government stations are using Mylar line in place of steel-cable guys for good technical reasons. Hams can, too. The perfect flexible insulator, it is especially good for transportables because it rolls up easily, and there are no insulators to lug around. For holding together multiwire arrays, there is hardly another material that has the strength and stability along with high insulating properties.

The traditional method of guying a tower is to use steel cable, broken every 10 to 20 feet with an insulator of the porcelain compression type. Because they must bear the same strain as the guy line these insulators must be large, and, together with the necessary clamping hardware, usually represent a significant portion of the weight of the guy. Where several guys are required, assembly becomes a major task. The intervals between insulators must be sufficiently short to avoid resonance at the highest operating frequency, or they may cause distortion of the antenna radiation pattern. Replacing the steel with synthetic-fiber line avoids these problems.

The use of nonconductive guys is not new. However, materials previously used for the purpose have had disadvantages. Glass-fiber line is not strong enough for heavy-duty work because it fatigues easily. Nylon stretches too much, and good old manila line made of natural fibers is subject to climatic deterioration. But the intrepid ham doesn't readily overlook a good thing just because it was tried once and didn't work. You've heard of Mylar, a polyester film invented by DuPont about 10 years ago. Mylar, as you buy it in the form of tape, stretches pretty badly, but its dielectric strength is so great that a strip one thousandth of an inch thick will withstand 4000 volts. Luckily, a method has been found for pre-stretching this film, heat-treating it, and weaving it into guy-line cable.

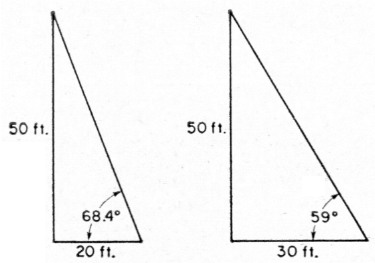

The stress on guy lines (excluding supports for wire-type antennas) is made up predominantly of wind loading - the pressure of wind against the surfaces of the tower and antenna - as transmitted to the guy wires. The calculation of guy-line loading has been discussed in detail in an earlier article in QST(1), and will not be repeated here. If the information is not set forth in their instruction sheets or other literature, tower manufacturers can supply a recommended guying pattern and guy-line breaking strength for the maximum antenna area for which the tower is rated. Other factors being equal, the stress on a guy line is in inverse proportion to the cosine of the angle that the guy line makes with the horizontal. In the case of a 50-foot tower with a guy anchored 20 feet from the base of the tower, (see Fig. 1) the angle works out to be 68.4 degrees, whose cosine is 0.38. If the guy anchorage is moved out to 30 feet the angle becomes 59 degrees, whose cosine is 0.51. This means that the stress on the guy anchored 20 feet from the base of the tower will be 0.51/0.38 = 1.34 times as much as on the guy anchored 30 feet away. Thus the guy-line stress decreases as the anchorage is moved farther from the tower base. As a general rule, the angle should not exceed 60 degrees or better yet, 50 degrees.

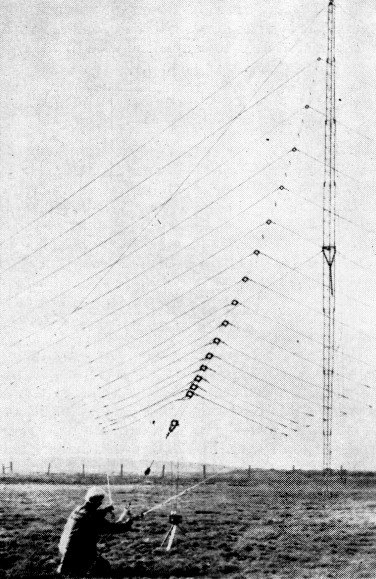

Log periodic antenna using Mylar-line side catenaries and stabilizers. (Grange Associates)

Fig. 1. Guy-line stress increases as the angle that the guy makes with the horizontal is increased.

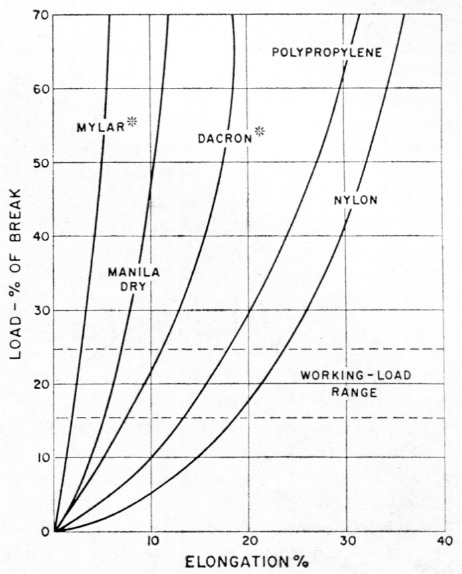

An added factor where synthetic-fiber guys are concerned is the amount of stretch under tension. A perfectly-balanced vertical tower would stand by itself in the absence of wind pressure or other external force, exerting no stress of its own on the guy. However, if the guy has elasticity which permits wind to push the tower out of plumb temporarily, a certain proportion of the weight of the tower is transmitted to the guy. The farther out of plumb the tower is permitted to tilt by the elasticity of the guy, the greater this additional stress becomes. If you have ever erected a small mast by pulling it up by its guys, you will have observed how much less pull is required when the mast is nearing the vertical position as compared to the pull required to get it started off the ground. All synthetic lines exhibit some elasticity but, as the graph of Fig. 1 shows, the stretch factor of Mylar line is about three times less than that of its nearest competitor - manila rope - over the working-load range, which is usually 15 to 25 per cent of the rated breaking strength.

Fig. 2. Graph showing relative stretch (initial, when new) in various types of synthetic-fiber lines with loading in terms of percentage of breaking strength. The usual working-load range is included between the dashed line. ® Indicates DuPont trade name.

Mylar line comes in kits of 50-foot multiples (100-feet minimum). The kits include clamps and thimbles which are used for fastening in a manner similar to wire cable. The amount of cable required for the job at hand may be estimated by considering that the guy is the hypotenuse of a right triangle, the two legs of the triangle being the distance from ground to the guying point on the mast, and the distance from the base to the anchor point. The required guy length is obtained by taking the square root of the sum of the squares of the two legs. For a guy fastened 50 feet above the base and anchored 30 feet from the base, the guy length will be √(502 + 302) = √(2500 + 900) = √3400 = 58 + feet. A foot or so should be added at each end for clamping.

In this day and age where antennas with controlled radiation patterns (directive antennas) are the vogue, non-conducting guy line can be a real boon, since it can be used with the assurance that the guys will not distort the predicted pattern.

Bill Hamlin, WA6SYE.